The K-25 plant at Oak Ridge was the single most expensive part of the Manhattan Project. It was cost about a fourth more than the entire Hanford site. Perhaps unsurprisingly, the building that housed it was pretty big — supposedly the largest single factory in the world under one roof, at the time that it was built.

I had thought about creating some kind of little graphic comparison to show you how big it was — you know, putting it next to The Pentagon and other large buildings — and then I realized that I wouldn’t really be flexing my geek cred, or taking advantage of a web medium, if I didn’t make a little custom mashup instead. So, I present for you a quick little app that I’m calling, How Big Was K-25?, where you can drag the footprint of K-25 onto anywhere in the world to make a size comparison:

(If you only see a blank spot above, or if you want to view it larger than it is displayed in the blog post, then click here to open the page in its own window. Note that there is a “rotate” button in the upper-left corner, if you want to re-arrange K-25.)

And yet… despite its cost, despite its size, when one thinks of images of the Manhattan Project, even images of Oak Ridge, views of the inside K-25 aren’t what comes to mind. We’ve all seen the images of the Y-12 “racetrack,” and many of us have seen images of the face of the B-Reactor, but what does a gaseous diffusion plant look like?

A reader asked this question in a comment on last week’s post, and it got me scratching my head, and asking around on Twitter. I got enough interesting results that I felt it was worth a post in its own right, as opposed to just a long comment. I can think of two major reasons why this sort of thing isn’t as common in the photos of the bomb project, which I’ll include at the end.

These photos were mostly taken by Ed Westcott, the official Oak Ridge photographer during the war (and after), and are hosted by the Oak Ridge Public Library. (Special thanks to the American Museum of Science and Energy for pointing this resource out to me!)

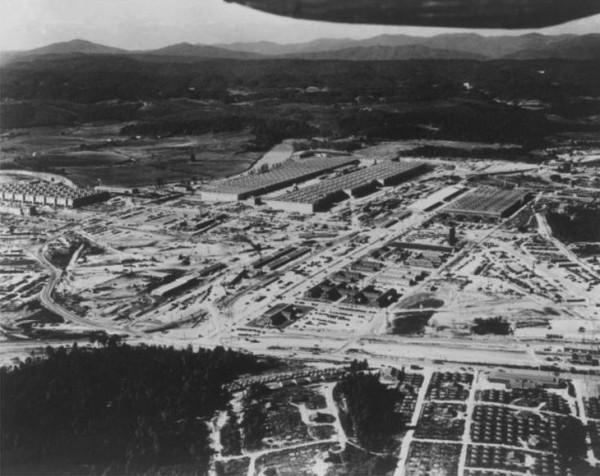

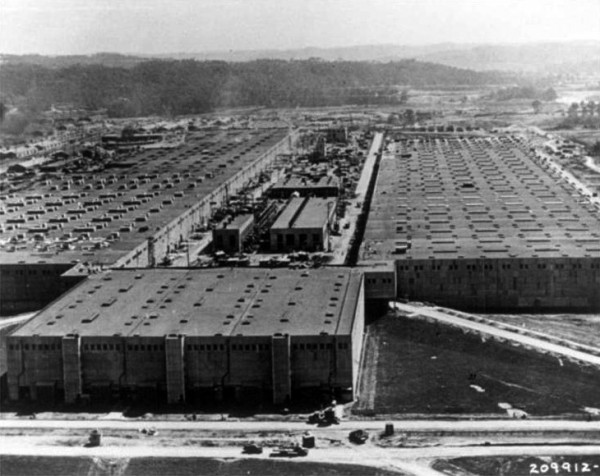

First we fly into the plant, in some typical pictures of its U-shaped bulk, but I like the juxtoposition as we get closer and closer. You can see some trucks at the very bottom center of the lower image, to get a sense of scale. It’s big.

We think of the signs in such an installation to be all about security, but these ones are all about cleanliness. This appears to be some kind of basic air-lock. I find that somewhat charming, though one knows that grime is something you probably don’t want in a gaseous diffusion plant, where every atom counts!

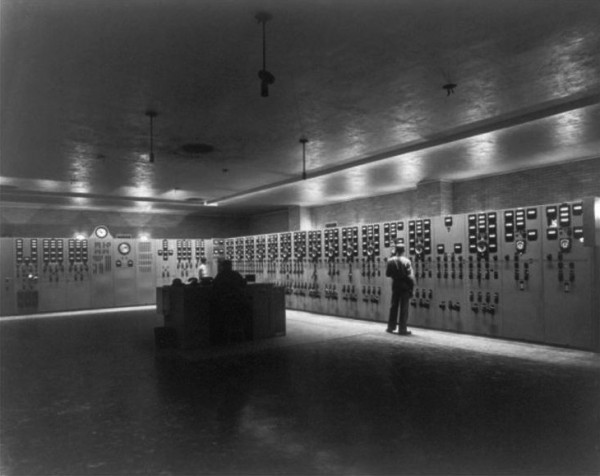

Two control rooms. I find the one on the bottom to be a wonderfully haunting photograph. I love the difference between the size of the room and the tininess of that table. It must have been a tremendous pain to keep something as interconnected and complex as the K-25 plant humming around the clock.

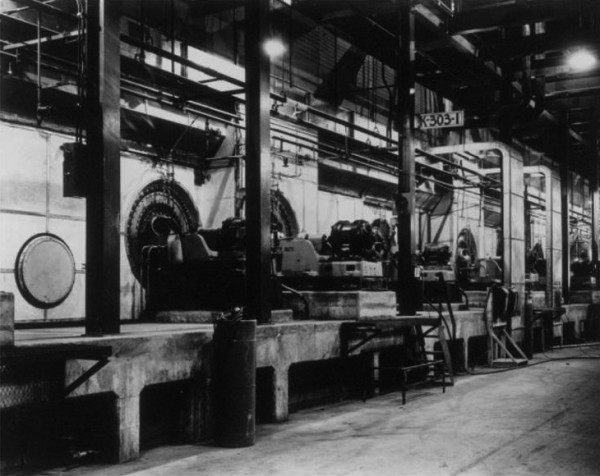

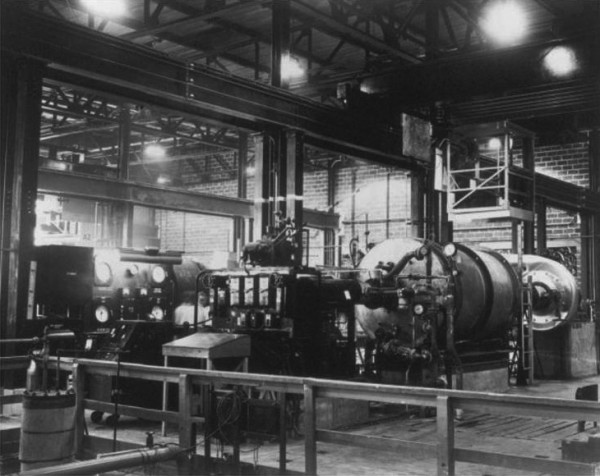

These ones all seem to show the insides of various stages of the cascade. As you can see from this plot plan, K-25 consisted of lots of individual “cells” that were linked together. Its vastness and bulk is mostly iteration of stages, like most (all?) uranium enrichment facilities — each stage doing a tiny part of the overall work.

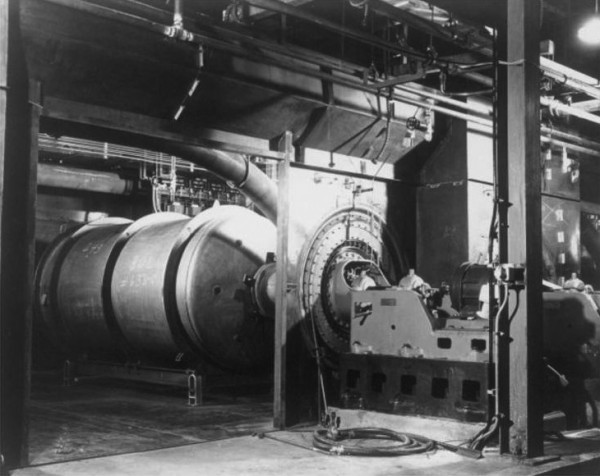

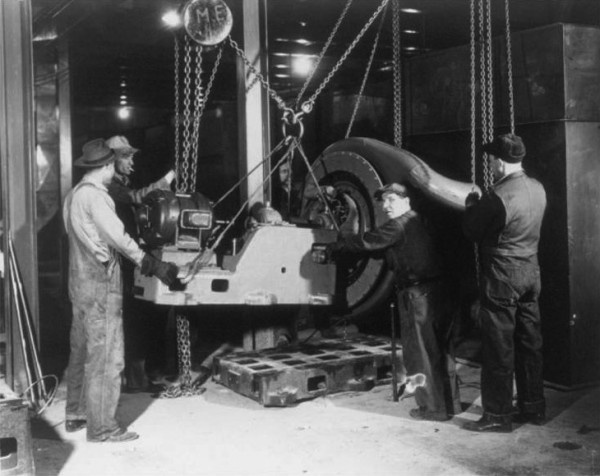

These ones I like because they help give you some sense of the size and nature of the equipment involved. Gaseous diffusion plants look like various pipes and pumps and big vessels. In a way, they are somewhat generic looking, which may be why they aren’t usually used to illustrate uranium enrichment, as I’ll speculate on a little bit below.

Lastly, a few color images, probably taken at a later date, from the Manhattan Project Heritage Preservation Association:

Both of these I like not only because of the color — how much of those paint jobs are post-1945, I don’t know — but also because the presence of people helps you get a sense of the scale of those vessels. They seem larger than the ones in the other photographs, so they may be later additions. Thanks to Jeffrey Lewis for pointing this out to me.

So why are these images dreadfully underrepresented in our collective imagination regarding the Manhattan Project? I offer three possible reasons.

One is the familiar problem of classification: gaseous diffusion was highly classified after the war. Unlike the electromagnetic enrichment method, or the basics of reactor operation, it wasn’t declassified in the early 1950s. There are still lots of things that are tied up tight as far as classification is concerned, despite the fact that gaseous diffusion is a pretty old technology, and arguably not the technology of choice for a modern proliferator (too expensive, too difficult).

Another is that gaseous diffusion arguably wasn’t as significant to the war effort as electromagnetic enrichment (though it wasn’t exactly insignificant, either); it came online a lot later, and really wasn’t perfected until after the war ended. Also, in comparison to the electromagnetic method, it also lacked as enthusiastic a booster as Ernest O. Lawrence, who was nothing if not entrepreneurial in promoting technologies that he was involved with.

And lastly, a potential other reason though is that as a concept it’s a bit harder to grasp, a bit hard to explain, and a bit harder to display visually, than other methods of enrichment. Electromagnetic enrichment is pretty easy to understand, and easy to diagram. And once you’ve seen how it works, suddenly images of Calutrons make a lot of sense — ah, there’s that C-shape. Rope them around a magnet and you’re done. It corresponds with nice intuitive notions of classical mechanics, and can be the source of all sorts of plain-language analogies (throwing heavier or lighter baseballs, for example).

Gaseous diffusion involves shooting gas through specialized barriers, relying on slightly different transit times, and visually, looks like just so many big tubs connected to one another. Internally it looks a lot like a lot of other anonymous industrial plants; its size, and its radioactivity, are perhaps the only things that make it obvious that it isn’t some kind of anonymous solvent factory. The kinds of diagrams explaining its operation that circulated in the early days were not exactly stimulating to thought, either.

All of this discussion of K-25, of course, is thoroughly in the past tense. Most of K-25 has been torn down; demolished. The DOE has been fairly unenthusiastic about preserving any of the K-25 buildings, despite their historical relevance. I think this is really, truly too bad. Whatever one’s feelings about the Manhattan Project, destroying historical sites doesn’t really help anybody. This is one of the reasons I’m a supported of the Atomic Heritage Foundation‘s efforts to have a number of the few remaining Manhattan Project sites declared part of a new Manhattan Project National Park. Aside from the possibility of using them as the focal point for interesting interpretations of our atomic history, it’s also necessary if we’re going to expect any remnants of these buildings to still be around in generations to come, as the Manhattan Project slides out of living memory. We can argue about the meaning of these sites for years and years — but only if we still have them to argue about.

Here’s an update on the tearing down of K-25. http://blogs.knoxnews.com/munger/2013/05/beginning-of-the-end-at-k-25.html

K-25 seems to feature very prominently in Denise Kiernan’s new book The Girls of Atomic City: The Untold Story of the Women Who Helped Win World War II. I haven’t read it, but I have listened to some interviews with Kiernan, and it sounds promising.

P.S. Naturally I tried superimposing K-25 on Fermilab. It just about fits within the Main Injector ring, but it dwarfs all our biggest buildings.

Cool photos! Thanks, Alex!

Fantastic stuff, thanks again for going the extra mile with this idea. Love the blog. You should sell out and put up a paypal button. I’d hit it!

Thanks! I had fun superimposing K25 on both The Forbidden City and Tiananmen Square in Beijing. Tiananmen is a huge square, having held about a million protesters in 1989. And yet K25 is almost exactly the same size as the square and the Great Hall of the People. Man, that’s a big building!

I think the interior shots, even more than the massive floor plan show how far this is from Fermi and co stacking up graphite blocks and uranium at Columbia, or (to make a more direct comparison), Alfred Nier working with his mass spectrometer, photo here.

Great post! Always original, unique, and inspired.

Alex,

Excellent. Here are a few paragrapghs from a talk I gave a few years ago about K-25 which may provide some background.

Stan

“The third enrichment process at Oak Ridge was the gaseous diffusion method based on research by the Nobel Prize winning scientist Harold Urey of Columbia University and his colleagues. As with his other atomic factories Groves recruited large industrial corporations to design, build, and operate what came to be known as K-25.

Designing K-25

To design K-25 Groves chose Percival C. (Dobie) Keith. Keith was a VP of the M.W. Kellogg Company and one of the top chemical engineers in the country. Keith, born in 1900, had grown up in Sharon, Texas and after college did three years of graduate work at MIT with a degree in chemical and electrical engineering. As an executive with Kellogg he was already knowledgeable about the secret research on isotope separation and had been on the OSRD Planning Board, a forerunner of the S-1 Committee, for one year. He first met Groves in December 1942 and they got on well. Initially he refused the job but his former Professor W.K. Lewis of MIT told him to take it. He demanded to be given complete responsibility and Groves gave it to him. A subsidiary of Kellogg, known as Kellex, was formed and eventually 3,000 personnel worked at headquarters, on three floors of the Woolworth Building in lower Manhattan, and elsewhere.

Building K-25

To build the plant Groves chose the J.A. Jones Company of Charlotte, NC. J.A. Jones had built more Army camps under Groves’ supervision than any other contractor in America and Groves knew Edwin Lee Jones, the eldest son of James Addison Jones well. The building was staggering in its scale, covering 43 acres. The main building resembled a squared-off letter U. Each side was 2,450 feet long and 400 feet wide, with the floor space approaching that of the Pentagon, another of Groves’ construction projects that was completed in January 1943. The peak labor force to build it occurred in April 1944 at 19,680 with many of those housed in the temporary facilities at nearby Happy Valley.

Operating K-25

Groves recruited the Union Carbide & Carbon Corporation to operate K-25. Some of their affiliate companies were already involved in Manhattan Project activities. The company came highly recommended by Keith and DuPont. The key person was James A. Rafferty a chemical engineer by training and executive VP since 1939. He was a dynamo within the company, a leader in the new industry of deriving synthetics from petroleum. Groves met Rafferty at the Union Carbide offices on the corner of 42 Street and Madison Avenue in New York City around Christmastime 1942. They liked each other immediately and Rafferty assembled a team that worked with Kellex and Jones as it was being designed and built so that it would be operating properly it when it was done. The total cost to build and operate K-25 was $512 million, which is approximately $10.7 billion in today’s dollars.

Three Problems

Let us briefly look at three seemingly overwhelming problems that had to solved if the gaseous diffusion method was to work. These examples show the ingenuity that expressed itself over and over during the Manhattan Project.

The first was to find someone to design and manufacture large metal diffusers, containers in which the barrier material that would separate the isotopes would be placed. On March 20, 1943 K.T. Keller, the President of Chrysler was contacted and a meeting with Groves, Nichols, and Keith took place in Detroit on April 2nd. KT was quite a figure in his own right. Born dirt poor in 1885 he pulled himself up by his bootstraps and after working at General Motors for 14 years came to Chrysler. He was a tough character, knew everything about Chrysler and was made president in 1935. KT was briefed that several thousand of these diffusers would be needed and they had to be able to resist the highly corrosive uranium hexafluoride gas. The only material that would resist the gas was nickel. Making them out of solid nickel was out of the question as it would have consumed the entire national supply. The logical solution was to plate steel with nickel. The attempts thus far had not worked as the gas ate through the plating. Chrysler was known for its plating innovations and KT accepted the challenge, and received a $75 million contract. He gave the problem to Dr. Carl E. Heussner the Director of the plating laboratory and the problem was solved in less than two months by the end of May. Within Chrysler the secret project was known as X-100. To manufacture and plate the diffusers Chrysler converted a Dodge automobile plant (then making tank transmissions and truck parts) known as the Lynch Road factory in eastern Detroit. Absolute cleanliness standards were imposed. Chrysler would eventually deliver over 3,500 of diffusers to K-25.

The second problem had to do with designing and manufacturing compressor pumps to force the gas through the cascades at high velocity. The crucial problem was that the pumps needed to have seals that were leak proof. They had to be resistant to the corrosive gas and work without any lubricants which would contaminate the process. Groves went to Allis-Chalmers, of Milwaukee, WI which was already building the gigantic magnets for Y-12. They were told to build a pump plant — and did so in 57 days beginning in April 1943 — but without the precise design for the pump, a typical Manhattan Project procedure. Dobie Keith recruited George Watts, the chief engineer of Standard Oil of Indiana, who was given primary responsibility and Groves called President Edward Seubert to have him released. The pump was actually invented by Judson Swearingen and Allis-Chalmers delivered 7,000 compressors to Oak Ridge on time.

The third problem was to design and produce a porous barrier or membrane that would allow the lighter U-235 atoms of the uranium hexafluoride gas to pass through but not the heavier U-238 ones and not be destroyed in the process. Much of the work was done at Columbia University. The holes had to be tiny, one-ten thousandth of a millimeter, could not become clogged, and must be tough enough to withstand high pressures. The preliminary designs were thumb-sized while several million square feet of the material eventually would be needed. One promising candidate was the Norris-Adler barrier, but the design ran into problems at the Columbia pilot plant. The material was brittle and the holes got clogged. A competing design was offered by Clarence Johnson, a Kellex engineer, with much help from others. Groves was faced with choosing which design would be used to produce on a mass scale. He initially chose the Norris-Adler design and hoped there would be improvements and a plant in Decatur, Illinois was being built to produce it. But by January 1944 the design looked less promising. After an all night drive through Indiana and half of Illinois Groves arrived at the Decatur factory for a meeting. He announced his decision to the startled executives and ordered the almost finished plant stripped of the just-installed equipment and rebuilt to manufacture the Johnson-Kellex barrier material. By the summer of 1944 large quantities of the material were being shipped to the Lynch Road facility to be placed inside the diffusers and from there on to K-25.

Conclusion

In conclusion K-25 made a valuable contribution to producing the uranium that went into the Little Boy bomb. On January 20, 1945 the first stages were charged with hexafluoride and throughout the next few months more stages were added. The production control committee produced a detailed plan at the end of February to integrate the three enrichment processes which occurred on March 12th. The S-50 output of approximately one percent was used as feed for K-25 which enriched it further to 7 percent and increasingly by the summer to over 20 percent. The K-25 feed was introduced into the Y-12 calutrons where it was further enriched to approximately 80 percent U-235. In this way 64 kilograms of HEU ended up in the Little Boy bomb.

After the World War II gaseous diffusion became the preferred method for enriching uranium in the U.S. and a level of 93.6 percent U-235 was set. At Oak Ridge between January 1946 and June 1954 K-27, K-29, K-31 and K-33 were added to K-25. By the mid-1950s the interconnected complex formed one continuous cascade of some 5,000 stages and by 1964 had produced 349 metric tons of U-235 (out of a total of 858 tons) according to a recently declassified DOE historical report on HEU production.

Two additional gaseous diffusion plants were built. The 1,812-stage Paducah plant in Paducah, Kentucky was completed in 1954. While it never produced HEU it did enrich uranium to 1 percent and then shipped it to Oak Ridge and Portsmouth for further enrichment. The 4,080-stage Portsmouth plant in Piketon, Ohio was completed in 1956. The AEC discontinued HEU production for weapons in 1964.”

“http://www.att.com/att/planner/#fbid=XlsDgBBJ4P-”

“Two additional gaseous diffusion plants were built. The 1,812-stage Paducah plant in Paducah, Kentucky was completed in 1954. While it never produced HEU it did enrich uranium to 1 percent and then shipped it to Oak Ridge and Portsmouth for further enrichment. The 4,080-stage Portsmouth plant in Piketon, Ohio was completed in 1956. The AEC discontinued HEU production for weapons in 1964.”

To add a bit,

1) key operations personnel trained at K-33 in Oak Ridge before Portsmouth came on stream. The individuals, about three assigned to each rotating shift were the supervisors and operations managers for the first shifts in Portsmouth.

2) The constant caravan between Oak Ridge and Paducah ran 24/7. Eighteen wheelers with a specially prepared trailer hauled three 10 ton cylinders of low grade U-235 from Oak Ridge to Paducah, loaded their tails product back onto the trailer and brought those cylinders back to Oak Ridge to be fed back into the cascade in the feed facility in K-33. Effectively the Paducah cascade was a stripping facility for the K-33 operation.

More than the physical size, complexity or cost, I find simply having the ability and audacity to build such a mega-project in such a short time staggering.

Would we be able to replicate such a feat of engineering/building today?

Even with no cost limits?

I am rather doubtful.

Comparing K-25 to the Paducah KY gaseous diffusion plant at 37° 6’31.04″N 88°48’29.44″W is interesting. Also, compare it to the Sedan Crater at the Nevada Test Site at 37°10’35.76″N 116° 2’36.37″W – 104 kilotons. The Sedan test was one of the more wacky nuclear era efforts, part of the Plowshares program that explored the use of nuclear weapons to dig holes (the fallout problem was not understood back then, apparently). NUKEMAPing Sedan with a 104 kt weapon gives a perfect fit, by the way.

There are a few more K-25 interior photos in this 16MB pdf file, from a 1997 DOE publication (focused on waste streams), Appendix B: The Eight Major Processes of the Nuclear Weapons Complex, which also has a lot of information on the other gaseous diffusion plants, plutonium production, etc.

http://www.factsofwny.org/117206.pdf

“Construction of the K-25 Plant was a major industrial effort. The Kellex corporation, of Jersey City, New Jersey, a subsidiary of the M. W. Kellogg Company designed the plant. Construction was managed by the J.A. Jones Construction Co. out of Charlotte, North Carolina, with the assistance of Ford, Bacon & Davis. The plant and equipment were created by companies from all areas of the country. The original K-25 converters (the corrosion-resistant tanks enclosing the diffusion barriers) were manufactured and assembled by the Chrysler Corporation in Detroit, Michigan. Half a million specialized valves were supplied by Crane Manufacturing Company while compressors designed to handle uranium hexafluoride were developed and supplied by the Allis-Chalmers Company based in Milwaukee, Wisconsin. ”

“Houdaille-Hershey Co. manufactured diffusion barriers at their Oakes Products Plant located in Decatur, Illinois. These diffusion barriers were made using nickel powder supplied by the International Nickel Co. plant in Huntington, West Virginia. Heat exchangers to remove the heat of compression were built by A.O. Smith Company in Milwaukee, Wisconsin and by Whitlock Manufacturing Company. Bart Laboratories, International Nickel, and Midwest Piping and Supply produced three million feet of special piping that could resist the corrosive effects of UF6. Many other firms supplied pumps, instruments, gauges and other parts.”

I see that a bill which would create Manhattan Project National Historical Park was passed in the House last week.

I just finished reading The Girls of Atomic City: The Untold Story of the Women Who Helped Win World War II. This post provides a nice accompaniment. Thanks!

You shoulda seen it in person! Everybody in my community either worked there or TVA. My Dad was a K25 fire and guard shift captain. There once was a train tour that included part of the plant.

If your sister is Betty I graduated from HS in the same class……..1952

[…] Project was big. But how big was it? There are lots of ways to try and convey the bigness. The size of the buildings and sites, for example. Or the cost — $2 billion 1945 USD, which doesn’t sound that big, even when […]

I was hired by Union Carbide Corporation Oct. 1, 1952 to be trained as a process operator at the K-25 gaseous diffusion plant(ORGDP) There were 83 others hired at the same time for the same type position. The course lasted 27 months and we were trained in the operation techniques and requirements in fourteen areas of the plant. We even worked a shift rotation(28 days) in the air plant, the water plant(sanitary) and the water cooling facilities(process.)

A typical shift rotation consisted of five days of classroom instruction and the other twenty three days operating in the area assigned to us for that period. The concept was designed by Roland Murphy who at the successful completion of our training was promoted to head of education for all of Carbide’s divisions of which there were nine at that time. He relocated to UC’s corporate office in NY and I lost touch with him after that.

We were trained in the flows of gas, pressure control, cascade flow, operating temperatures, barrier material, electric power consumption, water tower cooling, Freon cooling systems which were massive for the bigger cells, preparing a cell for required maintenance, cold traps, Hydrogen Fouride storage, purge and evacuation stations, tops purge, side purge, product withdrawal, electric and pneumatic instrumentation, handling of fluorine and chlorine trifouride cylinders, leak testing, the process seal, barrier tube manufacturing, control room operation, power distribution etc. We took a turn in each important aspect of a process stage, of which there were 4400 stretched out across a two mile long run of buildings. The plants were the original(K-25), K-27, K-29, K-31 and K-33 which contained the largest equipment housed in the third largest steel structure in the world at that time falling behind the Eifel Tower and the Empire State building. K-33 went on stream in mid 1954 and it’s dimensions were awesome. The single building was 81 ft. high, covered more than 32 acres, had two floors and a partial basement. It’s part of the cascade consisted of the main feed facility which fed the low grade uranium, 640 separation stages each one made up of a converter the size of a small house which contained 4000 individual barrier tubes(tube bundle), an axial compressor and a 2000HP GE or Westinghouse electric motor. The motors were each mounted on a 3ft high slab of concrete and were the size of a compact car. The pipes made of monel steel were one each 60″ diameter, 24″ diameter and 18″ diameter.

The supply voltage to each of the 640 stages was 4480AC and during normal cascade operation would float around 600-800 amps. On down surges which were infrequent I’ve seen all the stages in a cell pinned at 1000 amps. When the single plant was completed and on stream it used more electric power than the city of Chicago. When all the gaseous diffusion plants were completed and on stream, Oak Ridge, Portsmouth, Paducah etc. combined they consumed 10% of all the generated power in the United States.

I worked as a process operator in the three axial plants, K-29, K-31 and K-33 for ten years then transferred to the computer center and finished my 41 years there. I retired in 1993.

I’ve always told my children that I’m one of the luckiest people in the world. I only completed HS and the 27 months I was being trained by Union Carbide was truly where my education came from. I did complete a course in electronics during the mid 60’s but that was mostly because of my interest in ham radio(K4ESW) licensed in 1959.

An Historical Event Which Might Be Of Interest To Some:

THE BACKGROUND

In October 1952 I reported for my first day of work as a trainee to be a process operator at the Oak Ridge Gaseous Diffusion Plant(ORGDP) which was the uranium processing facility being operated by Union Carbide for the old AEC, now DOE. An unbelievable facility which took raw uranium as it appears from the mine, fluorinated it and placed it in cylinders so they could heat it into a gaseous state and feed it into a 4400 stage cascade which pumped it through converters containing barrier tubes from one stage to another until at the top the uranium 235 isotope was withdrawn in 5″ diameter cylinders, 30 inches long…always safe. The withdrawn material was approximately 97% pure. It was the plant from which the first material was harvested for the atomic bomb that was dropped on Hiroshima in 1945. ORGDP’s highest assay material at that time was about 20% U-235. The Y-12 facility used our output and further refined it using calutrons and produced weapons grade material. The Nagasaki bomb was a plutonium bomb and that material came from one of the western AEC/DOE sites. After the bombs were delivered the original calutrons were shut down and after that K-25 did all the uranium enrichment. There were a couple of calutrons left in operation to produce some material for medical research until about 1970. The gaseous diffusion process was shut down in 1985 and the entire facility became a multi billion dollar demolition and decontamination activity.

THE MESS

In January 1953 an operator was handling a feed cylinder in the first unit (K-402-1) of the K-27 facility and just as he was connecting a 1 1/2″ copper line it ruptured spreading the approximately ten tons of low alpha/beta assay radioactive contamination over two floors of a quarter mile long building. A floor above the spill, a quarter mile away…the condensing uo2f2 formed icicles two feet long hanging from 6″ steel construction beams and tons of the material was in a powder form on the floors.

THE CLEANUP

All of the 84 trainees and about 25 other employees who could be spared to help were assigned to four rotating shifts which worked 24/7 for about three months till mid April 1953. We were issued plain white coveralls, yellow skull caps, shoe covers and no type of mask. That would literally be a joke to anyone working in toxic contamination today. When they dismantled the same plants after they had been “purged to a negative” and shut down those doing the work, some continuing as we speak, wear/wore double impermeable suits with a positive pressure on the inside provided by 110# air pressure so no type of exposure to toxic material is/was possible.

The average age of our trainee group was 20 and about 30-35 for our supervisors. The supervisors would joke and cut up with us and were like “one of the boys.” I was barely 18 and several of my buddies were about the same age. After we dressed in our “protective clothing,” we began in the areas where the icicles formed and broke them off and placed them in boxes about 3x3x2 to be hauled away by coded chemicals in 2 1/2 ton trucks. We would use large sponges dipped in a barrel of solvent and wash down each one of the thousands of steel beams in the large processing facility. One night on 12-8 shift the boys were feeling frisky and somebody threw one of the big wet sponges at another trainee and a huge war started among nearly everyone…even our supervisor. Two of the boys got mad and had a fight in one of the airlocks and were suspended for three days as disciplinary action.

We had so many vacuum cleaners running that we had to station an employee near the electrical panels at the back of the 300′ wide buildings to reset circuit breakers when they tripped due to overload. Guess how they labeled the bags which no doubt ended up in a trash dump or land fill? “Class D Household Filth.” There were no toxic or radioactive admonitions whatsoever on any of the material we cleaned up from the facility.

I believe this was the largest and most troublesome release and consequent cleanup in the history of the K-25 plant.

I lived next door to you at 366 West Outer Drive – My dad Gene Mayer worked at K-25, too (Carbide & Carbon Chemical Corp). I remember waking up early in the morning to hear you practice the piano.

I enjoyed reading your comments about your work at K-25.

I remember you Fred. We used to gather in front of the street lights in the summer time and play till the parents called us in. Do you remember the Midkiffs…Max and Janet. You might remember that some mentally retarded guy murdered their dad, Romie Midkiff while he was fishing from the bank below K-25 on the Clinch river. Do you happen to know what happened to the family?

We moved away from W. Outer about 1946/47. We lived on Pacific Rd. near the intersection of Pennsylvania, NY, Vermont and W. Tennessee.for about ten eight years and moved to Kingston.

To any old timers:

Bobby Copeland has written another book and it’s entitled, “Oak Ridge The Way It Was”

I’m sure anyone who was an early Oak Ridger would find it interesting.

Mr. Finch

Nice reading about those who were there and the stories that many had.

My dad worked for Kellex in Oak Ridge. Had memoirs otherwise said nothing. Was at Woolworth building. He on 3rd floor and Groves 4th. Don’t know when they went there and for how long.

Like to buy a keepsake. Any ideas? Knew many from B-29 Enola Gay and Bockscar.

Let me know.

Thanks,

dave

Been to Oak Ridge on the train that surrounded K-25.

My family has also taken the little train tour around K-25. It’s a shame that soon there will be little to even recognize as part of the complicated process which was operational for forty years there, 1945 to 1985. Ironically three things happened almost simultaneously about 1985:

1) The big poisonous gas leak in a Union Carbide plant in India which killed over 500.

2) The gaseous diffusion cascade shut down. The highly enriched uranium(HEU) part had been shut down for more than 20 years….1964

3) A new contractor took over the operations, Martin Marietta. Ironically numerous activities continued to operate full bore for years. The MAN project, Centrifuge research, the activities at K-1007 which had one of the largest mainframe computing centers in the southeastern U S continued to operate doing work for all Oak Ridge plants and Paducah, Ky until 1994 when they really became serious about closing down the remainder of the activities. Since then decontamination and demolition has been the name of the game. The government has already spent billions trying to clean up the residue from all those years of operation. It continues as we speak.

The whole series of ultimately five “K” buildings operated as one long process – a building that covered an area so big that if you threw in a POPE you could call it the sovereign state of Vatican City ….

You’re exactly right. Folks who weren’t around a plant like that cannot possibly have any idea of the size and scope of the project. The plant where I was first assigned in 1954(K-33) covered 32 acres. In the late 50’s on warm summer nights after I had completed my data recordings and routine inspections I would go to the roof to check the huge storage/overflow tanks which returned the oil flow to motor and compressor bearings and stay for a couple of hours on clear nights to watch the recently orbited satellites as they passed above every hour and a half. That building was the third largest steel edifice in the world at that time falling behind the Eifel Tower and the Empire State building.

My dad was Andy de la Garza who came to K-25 in the very early days, I think in 1943 or 1944, from New York. I think he worked for Kellex, but I’m not 100 percent certain. He worked at K-25 for over 40 years. At his retirement, he was in charge of combined operations for the K-25, Paducah and Portsmouth plants.

I am interested in hearing from anyone who knew him and/or worked for or with him at K-25. He has been dead for many years and I am curious about his work and career. He did not share anything about his work with his family.

Please contact me by e-mail at: dogwooddaughter@dogwooddaughter.com Thanks, Martha Fowler

This forum appears to be at best dying and possibly dead.

My Dad was Spencer F. (Sam) Finch and he worked at K-25 from April 1944 till his retirement in July 1973. He was a department head in the maintenance division. I’d like to discuss any plant activity with anyone who worked in any capacity at the plant during those years.

I can also be reached by mail at Finley6_2000@yahoo.com

My Dad was Ellis Crouch (now deceased). He worked at Carbide and Carbon chemical (Clinton Eng) from 9/1946 to 12/1949 and at the Paducah Gaseous Diffusion Plant from 4/1952 to 4/1954. He never spoke of any of this. I think he was a guard. If anyone knew him, I would love to learn more about his time there.

Patricia Crouch (Myers)

[…] from the Department of Energy. Part of the reason for wanting something like this is evident in the DOE’s destruction of K-25 — the DOE is not really about preservation, and if these sites are not being used by them, they […]

And part of it just might be to keep facts out of the public forum:

An Historical Event Which Might Be Of Interest To Some:

THE BACKGROUND

In October 1952 I reported for my first day of work as a trainee to be a

process operator at the Oak Ridge Gaseous Diffusion Plant(ORGDP) which was the

uranium processing facility being operated by Union Carbide for the old AEC, now

DOE. An unbelievable facility which took raw uranium as it appears from the

mine, fluorinated it and placed it in cylinders so they could heat it into a

gaseous state and feed it into a 4400 stage cascade which pumped it through

converters containing barrier tubes from one stage to another until at the top

the uranium 235 isotope was withdrawn in five inch diameter cylinders, 30 inches

long always safe. The withdrawn material was approximately 97% pure. It was the

plant from which the first material was harvested for the atomic bomb that was

dropped on Hiroshima in 1945. ORGDP’s highest assay material at that time was

about 20% U-235. The Y-12 facility used our output and further refined it using

calutrons and produced weapons grade material. The Nagasaki bomb was a

plutonium bomb and that material came from one of the western AEC/DOE sites.

After the bombs were delivered the original calutrons were shut down and after

that K-25 did all the uranium enrichment. There were a couple of calutrons left

in operation to produce some material for medical research until about 1970. The

gaseous diffusion process was shut down in 1985 and the entire facility became a

multi billion dollar demolition and decontamination activity.

THE MESS

In January 1953 an operator was handling a feed cylinder in the first unit

(K-402-1) of the K-27 facility and just as he was connecting a 1 1/2 copper

line it ruptured spreading the approximately ten tons of low alpha/beta assay

radioactive contamination over two floors of a quarter mile long building. A

floor above the spill, a quarter mile away the condensing uo2f2 formed icicles

two feet long hanging from steel construction beams and tons of the material

was in a powder form on the floors.

THE CLEANUP

All of the 84 trainees and about 25 other employees who could be spared to

help were assigned to four rotating shifts which worked 24/7 for about three

months till mid April 1953. We were issued plain white coveralls, yellow skull

caps, shoe covers and no type of mask. That would literally be a joke to anyone

working in toxic contamination today. When they dismantled the same plants after

they had been purged to a negative and shut down those doing the work, some

continuing as we speak, wear/wore double impermeable suits with a positive

pressure on the inside provided by 110# air pressure so no type of exposure to

toxic material is/was possible.

The average age of our trainee group was 20 and about 30-35 for our

supervisors. The supervisors would joke and cut up with us and were like one of

the boys. I was barely 18 and several of my buddies were about the same age.

After we dressed in our protective clothing, we began in the areas where the

icicles formed and broke them off and placed them in boxes about 3x3x2 to be

hauled away by coded chemicals in 2 1/2 ton trucks. We would use large sponges

dipped in a barrel of solvent and wash down each one of the thousands of steel

beams in the large processing facility.

We had so many vacuum cleaners running that we had to station an employee

near the electrical panels at the back of the 300ft. wide buildings to reset

circuit breakers when they tripped due to overload. Guess how they labeled the

bags which no doubt ended up in a trash dump or land fill? Class D Household

Filth. There were no toxic or radioactive admonitions whatsoever on any of the

material we cleaned up from the facility.

I believe this was the largest and most troublesome release and consequent

cleanup in the history of the K-25 plant.